The public transport industry’s recovery from the COVID-19 pandemic is being propelled by digital connectivity solutions which provide real-time or on-demand access to data by both passengers and operators. Railway infrastructure maintenance represents one area currently undergoing such a process of digital transformation.

The ability to accurately determine the location of issues along a track helps ensure a resilient and reliable “Predict and Prevent” maintenance strategy; better railway infrastructure maintenance reduces the time needed to detect and resolve an issue, delivering a better performing railway at a lower cost, and ultimately helping offer the travelling public a more reliable service.

Taking Advantage of Icomera’s Centralised Connectivity Platform

In a recent UK trial, Network Rail has provided an enterprising example of how Icomera’s centralised connectivity platform can be leveraged by infrastructure owners and operators to support solutions which improve operational efficiency.

Modern railway operations need better positioning data than those traditionally offered – Currently, the industry principally relies on using the Global Navigation Satellite System (GNSS), which is effective in open sky situations but has various limitations. In order to tackle these issues with GNSS-based systems, Machines With Vision has developed a highly accurate rail positioning technology called RailLoc, which uses sensor fusion to combine satellite positioning with computer vision. As a result, RailLoc delivers 1 to 2 orders of magnitude better positional accuracy than is achieved by industry standard GNSS-based solutions.

The RailLoc system works by using a pair of cameras mounted under the train to map thousands of Visual Waypoints per kilometre. These Visual Waypoints are accurately geolocated over the entire railway network, achieving better than 1m absolute accuracy that continues to improve run-on-run. The benefits of RailLoc are not limited to condition monitoring. RailLoc is evolving into a geo-location platform for railway infrastructure owners and for train operators who need access to a highly accurate record of train movements and accurate track centreline maps.

Explaining the RailLoc solution, Machines With Vision’s Founder and CEO Anthony Ashbrook said: “Getting actionable insights from data recorded with on-train sensors needs precise run-on-run data alignment – we call this Mobile Sensor Data Mapping. Using our low-cost on train sensor, our cloud-based data processing and Icomera’s excellent connectivity platform, we have demonstrated the future of railway infrastructure monitoring.”

The RailLoc Trial and its Results

Funded by the Rail Safety and Standards Board (RSSB) as part of its TOC17 innovation competition, the RailLoc trial was performed in collaboration between Network Rail, Icomera and Machines With Vision, supported by Truvin Analytics.

The purpose of the project was to deploy RailLoc in an operational railway setting, to test the solution at scale, and to identify the benefits for the railway industry and for passengers. To this end, in September and October 2020 a RailLoc sensor installed on Network Rail’s New Measurement Train (NMT) travelled on the UK network, acquiring data to validate the absolute positional accuracy and run-on-run repeatability of the sensor, and compare it to an industry standard GNSS-based solution.

Icomera’s centralised connectivity platform played an integral role in the trial, delivering remote access to RailLoc’s equipment and allowing real-time data offload. Providing immediate access to the data that the RailLoc sensor captured reduced the need for site visits (e.g. to unplug / replace hard drives), simplifying the process for all sides. The project was further supported by DG8 design and engineering, a division of Icomera UK, who did the on-train design for both the Icomera and RailLoc equipment.

Norman Gerrard, Icomera UK’s Head of Engineering, commented: “By supporting innovative new solutions, such as RailLoc, which demonstrate the operational value of improved rail positioning, Icomera’s technology is continuing to help drive the industry’s data-driven digital transformation.”

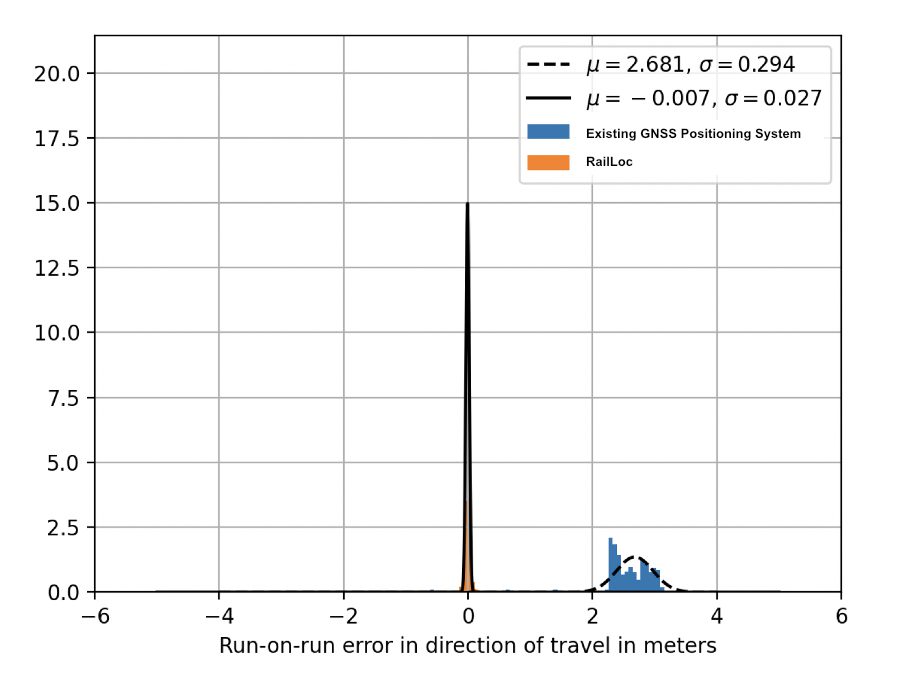

During the trial, RailLoc’s run-on-run positional accuracy was quantified over a 225km section of the UK mainline, demonstrating a standard deviation of 70mm, with 85% of measurements within 100mm. This highly accurate positional data has been used to automatically align run-on-run overhead line condition data successfully. Tests performed as part of the project provide evidence that RailLoc improves repeatability, when compared to the existing GNSS-based positioning system, by a factor of 100. The RailLoc solution has an average error variance of 27mm, while the existing GNSS positioning system has an average error variance of 2.7m.

Commenting on the trial, Network Rail’s Principal Engineer for Mobile Monitoring, Kevin Hope, said: “This trial has been a huge success, despite the challenges of Covid, due to the dedication of all the parties involved. The ability to locate asset data to the level of accuracy possible with RailLoc has the potential to significantly improve our current measurement and maintenance of the network. In the near future, as more and more data is collected about the condition of our assets, from multiple sources, including passenger carrying trains, the ability to combine and accurately align these datasets and use them to understand root causes and predict and prioritise maintenance activities is fundamental.”