Network Rail: Visual Inspection Unit Conversion Project

The Challenge

Manual S&C inspections bring risks to engineering teams. Following several serious incidents, Network Rail sought a proof-of-concept which would demonstrate a viable alternative to on-foot visual inspections.

The Solution

Icomera’s design and engineering division, DG8, was assigned as the lead supplier, responsible for delivering a turnkey service for Network Rail in which it would oversee all aspects of project management, design, and installation.

The Results

The project won ‘Safety Achievement of the Year’ at the National Rail Awards, demonstrating the power of leveraging connected technologies to ensure both safety and operational efficiency through preventative means.

Key Icomera Solutions

Design

Engineering

Installation

The Urgent Need to Address Two Key Challenges

Reduce Risks to Railway Staff

Issues surrounding track worker safety are treated with utmost priority by Network Rail – the owner and infrastructure manager of most of the British railway network.

Currently, Network Rail employees spend hundreds of thousands of hours on track for switch & crossing (S&C) inspections. However, switches and crossings are the highest risk asset in track engineering. Network Rail standards require S&C inspections to be carried out up to weekly in some areas. This is sometimes done during the day (causing disruption to passenger and freight services) but more often done manually at night by a track engineer who walks along the track during a possession and looks at the asset using just a torch.

Manual S&C inspections bring risks to engineering teams. Following several serious incidents, Network Rail sought a proof-of-concept which would demonstrate a viable alternative to on-foot visual inspections, meaning that some inspections could be diverted to the safety of an office.

Switches & Crossings are the highest risk asset in track engineering

Switches & Crossings are the highest risk asset in track engineering

Improve Network Infrastructure Management

By guiding trains from one track to another, switches and crossings play an integral role in the life of the railway.

However, they are very prone to wear and tear because trains frequently travel over them, meaning that they need to be monitored and replaced regularly. With 20,000 miles of track for Network Rail to maintain, that’s quite a job for its staff to do manually out on foot!

Every year, several low-speed train derailments occur on the network due to issues in which S&C are at fault. These derailments cause significant disruption[1]; and they also require large numbers of engineering staff to be (re)allocated to help resolve the problem, which incurs its own staff safety risks, in addition to cost and logistical issues.

Network Rail were therefore keen to implement a solution which would help to accurately determine the location of any issues along the track and ensure a resilient and reliable “Predict and Prevent” maintenance strategy. If successful, they would improve operational efficiency on the network, ultimately helping offer the travelling public a more reliable service, while maintaining the network at a lower cost.

About the Project

DG8’s Role as Lead Turnkey Supplier

Given the pressing need to address these two challenges, Network Rail sought a train-based solution capable of performing automated rail line inspection, which it could commence testing in under one year. A multi-company project team was formed to design and build a swift solution.

Icomera’s design and engineering division, DG8, was assigned as the lead supplier, responsible for delivering a turnkey service for Network Rail in which it would oversee all aspects of project management, design, and installation.

Re-engineering Older Rolling Stock to Bring Benefits

Network Rail initially selected two retired Cl153 units, which it had leased from Porterbrook, to be converted into Visual Inspection Units (VIUs) for the project. As well as being easy to drive / maintain and reliable to operate, Network Rail’s selection of older rolling stock such as the Cl153s made perfect sense given their availability, and the tight timescale being worked to.

Furthermore, over the longer-term, being able to extend and enhance the life of older rolling train stock such as the Cl153s will play a significant impact in supporting the transport industry’s overarching goals of sustainability and cost-efficiency. It’s interesting to note that retrofitting new and advancing technologies accounts for at least 60% of DG8’s active projects at any given time.

However, (re)designing and delivering onboard equipment and systems on older rolling stock brings its own set of challenges, the principal of which are (1) the limited available space and (2) the need for integration for existing onboard systems.

Supporting Complex Digital Onboard Solutions

To achieve the project goals set out by Network Rail, the unit conversion of the Cl153s was based around integrating three complex digital solutions:

- A track condition and geometry monitoring system enabling non-contact measurement of railroad track

- A camera system recording images of the track and uploading the footage back to Network Rail’s Video Management System (VMS)

- A positioning system that accurately tags the data from the other systems with the location on the network

DG8 worked collaboratively with the industry-leading solution providers involved to accommodate their requirements through intelligent, space-efficient design both to the vehicle exterior and interior.

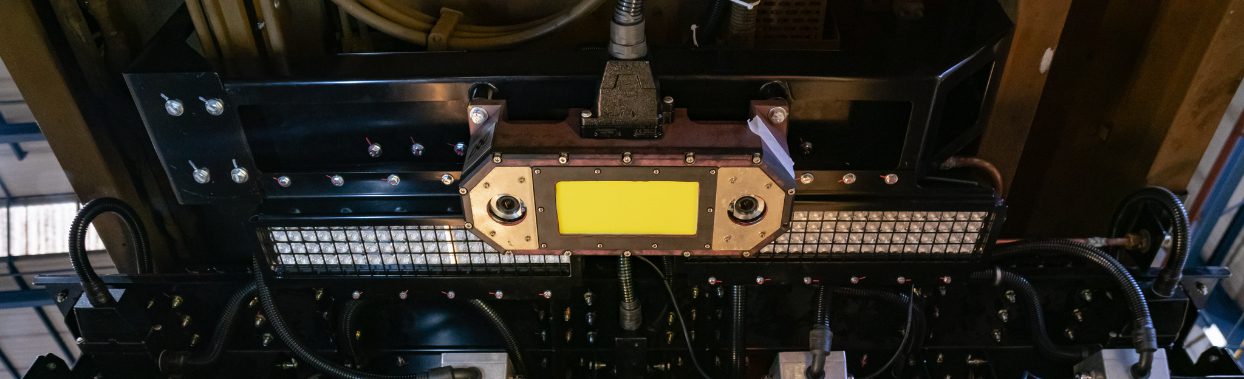

The VIU conversion units have each been equipped with eleven cameras which can record thousands of high-resolution images at high speed (eight at the front, one underneath, and two at the back). Mounted approximately 20cm above the rail, the cameras capture an area of up to 40cm wide, delivering high-fidelity images. Since the image resolution is good enough to inspect (for example) an individual bolt, S&C checks can be performed remotely based on data received from the VIUs.

Line scan cameras are installed underneath the train

Line scan cameras are installed underneath the train

An Innovative Hybrid Power Solution

The train systems required a hybrid power source with multi-mode controls to support recording while in service, and post-processing while in sidings. DG8’s solution was to install an internal generator and supporting lithium batteries working in tandem.

A distinction was drawn between the critical (“essential”) and non-critical (“secondary”) onboard systems. The generator powers both the “essential” and “secondary” circuits while the train is running – But when the train is shut down at the end of a shift, the generator closes down and some services (e.g. non-essential lighting) are switched off, while the critical systems continue to receive constant power via the lithium batteries.

The lithium batteries have a capacity of 600 Amp hours, 48V, which can power the kit for approximately 3.5 days. When the batteries begin to lose their charge, the generator automatically starts up and charges them until they are full again, before switching itself off. This ensures that the train remains permanently powered and ready for operation.

Since the VIUs essential systems are permanently powered, they can constantly transmit data back to The Cloud; this allows Network Rail to access the systems 24/7. Should the train be operating in bad reception areas or working in tunnels, the kit is able to transmit the data after the shift has finished. Even after the driver has gone home, the train remains powered and transmits.

DG8 designed the Visual Inspection Units with a hybrid power solution using a battery charger and supporting lithium batteries

DG8 designed the Visual Inspection Units with a hybrid power solution using a battery charger and supporting lithium batteries

What Network Rail Say:

“[The project’s] return on investment is fast, and if it saves one more death on the railway it will have paid for itself a hundred times over.”

Project Lead, Network Rail

What We Say:

“Working as part of this innovative Network Rail project, it’s been a pleasure to demonstrate DG8’s capabilities to deliver turnkey services within an ambitious timeframe”

Mark Hoptroff, Director, DG8 Design and Engineering

Line scan cameras are installed underneath the train

Line scan cameras are installed underneath the train DG8 designed the Visual Inspection Units with a hybrid power solution using a battery charger and supporting lithium batteries

DG8 designed the Visual Inspection Units with a hybrid power solution using a battery charger and supporting lithium batteries